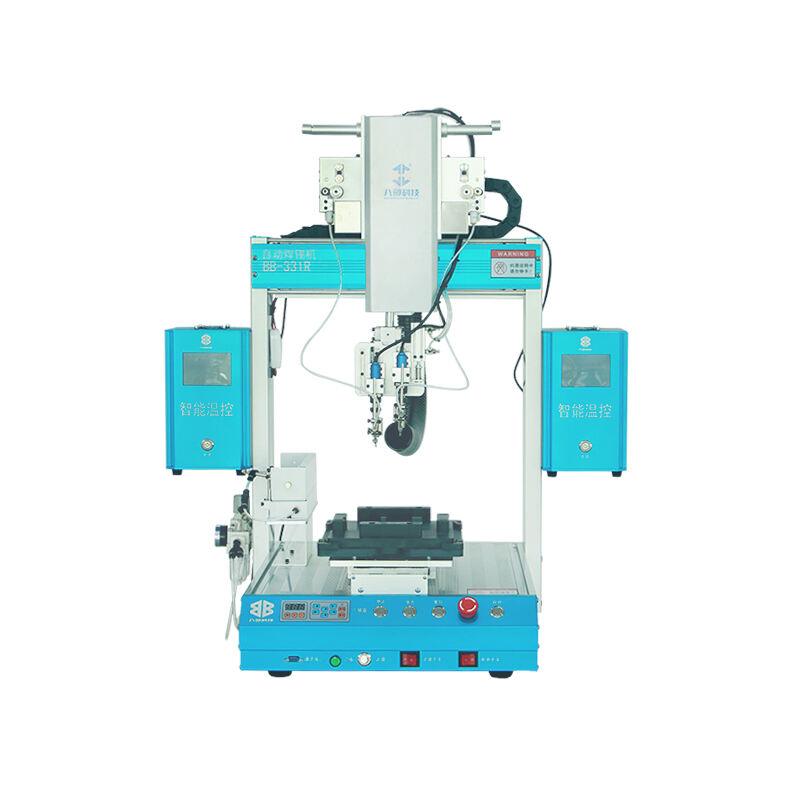

Boost your soldering output with the BB-331RHT dual-head machine. Ideal for high-volume production lines, it offers fast switching and precision soldering. Wholesale orders available.

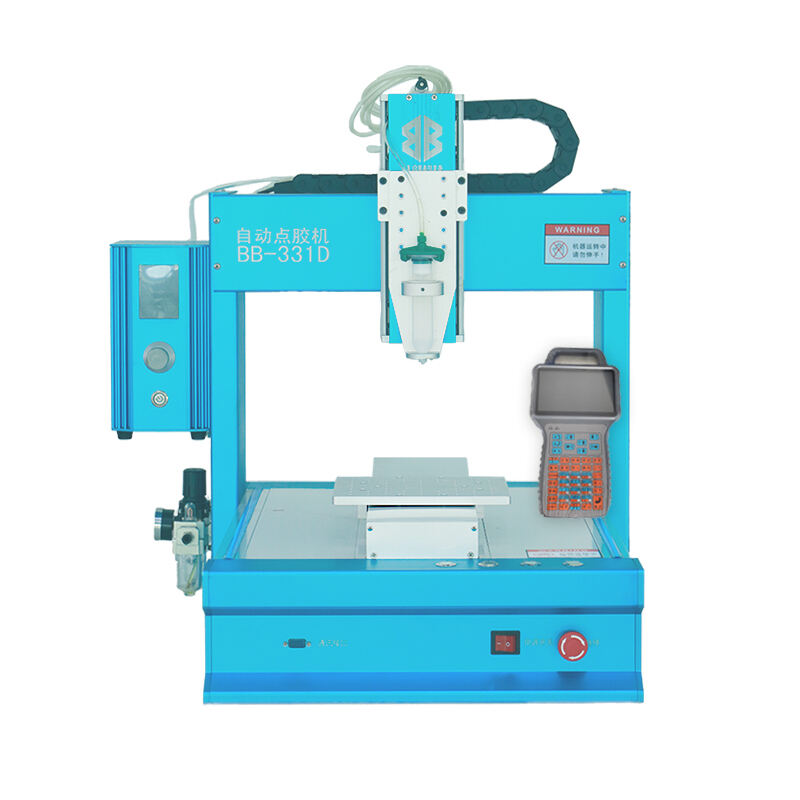

Optimize your production line with the BB-331D automatic dispensing machine. Achieve precise and consistent dispensing with Babu Technology.

Transforming Industries with Automation: From Medical Devices to Aerospace, the Automatic Lock Screw, Glue Dispenser, and Wire Soldering Machines Drive Quality and Efficiency.

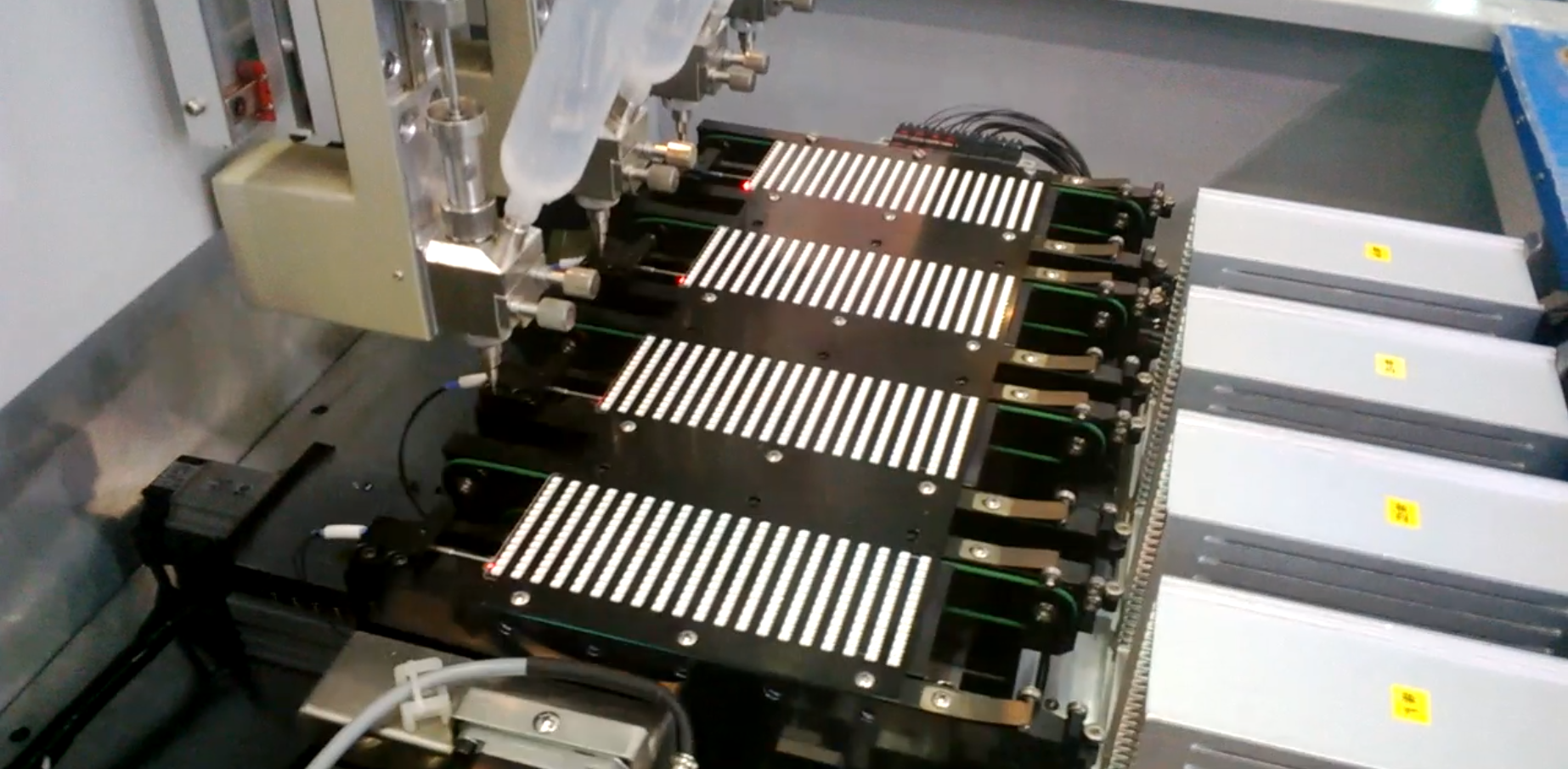

The design and implementation of the automatic loading and unloading dispensing machine is a complex process, involving the integration of many technical fields, including automatic control technology, computer vision technology, precision motion con...

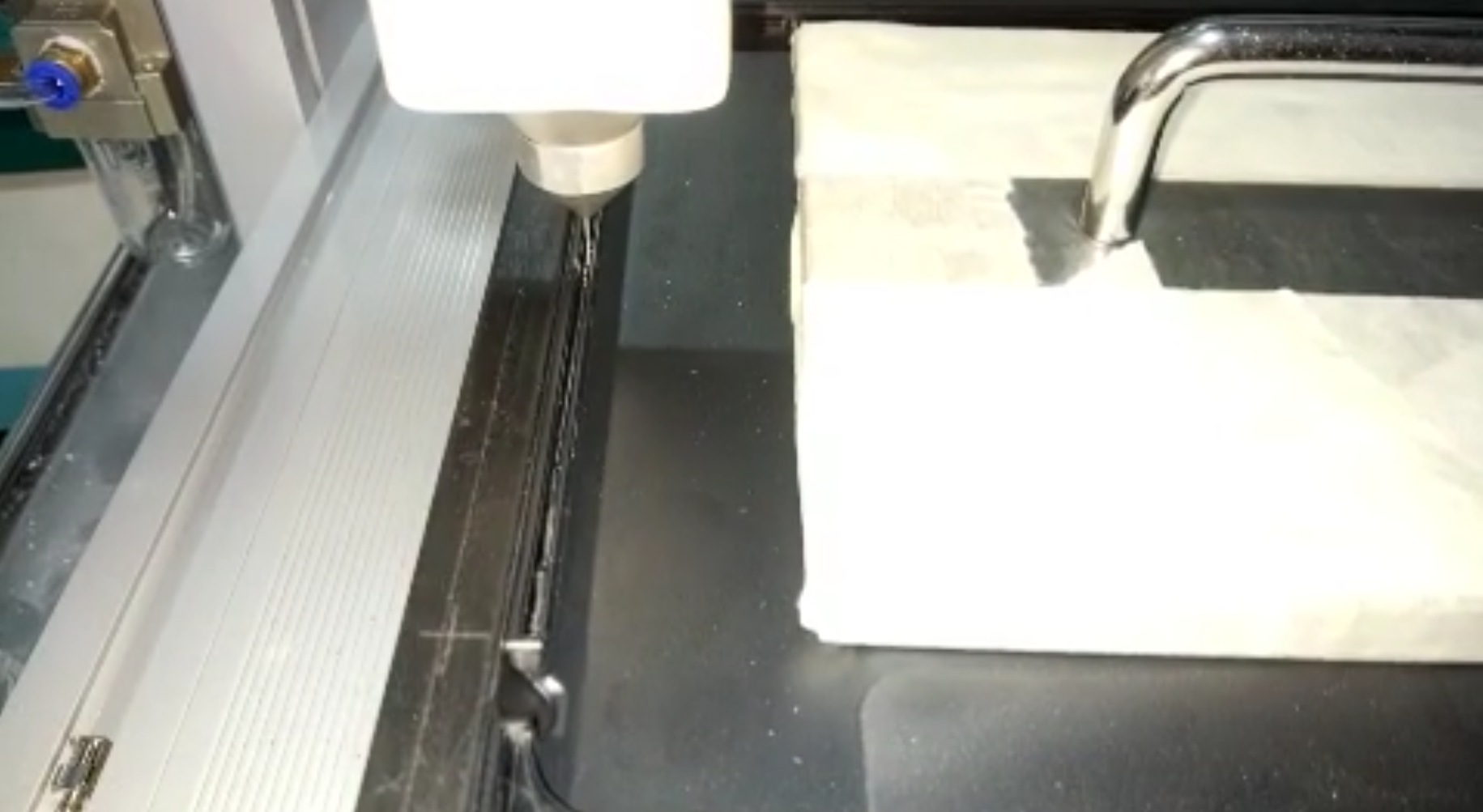

The application of BB-7441D automatic dispensing machine in the production of automotive filter elements is mainly reflected in improving production efficiency, optimizing product quality and reducing labor intensity and manufacturing costs.BB-7441D ...

Anaerobic dispensing machine is a kind of equipment that applies anaerobic glue, mainly used in mechanical manufacturing to improve product quality and economic benefits, while extending the service life of equipment. Anaerobic adhesives have a uniqu...

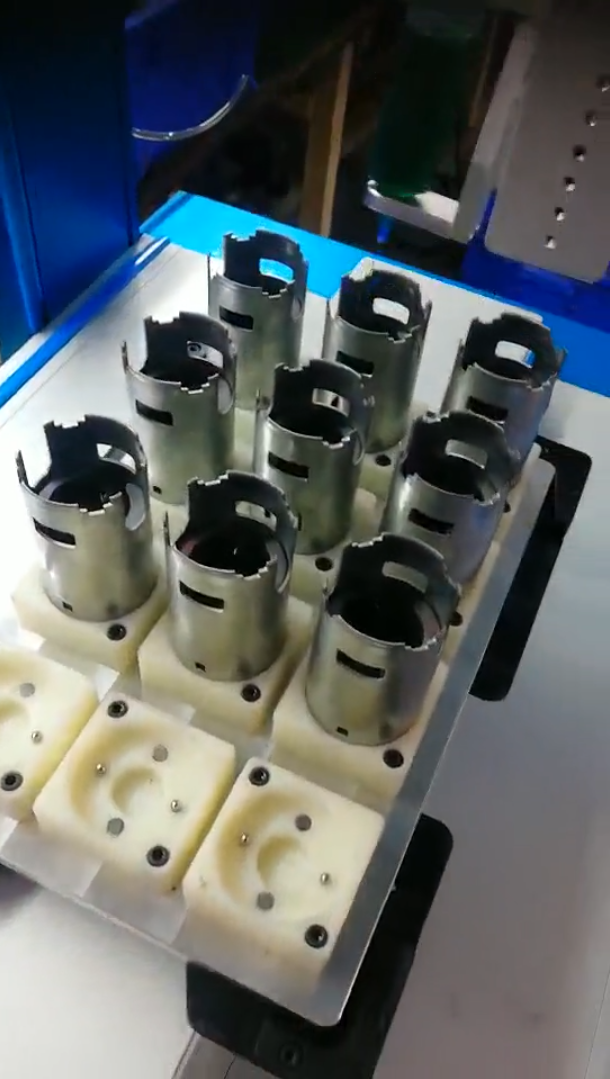

Babu motor rotor automatic dispensing machine is an efficient and accurate automation equipment, which is widely used in electronic component manufacturing, circuit board assembly, integrated circuit packaging and other industries. The device realize...

The automatic glue dispenser and hot melt glue machine ensure precise and consistent glue application, while the lock screw and wire soldering machines provide meticulous, error-free operations, greatly improving product quality.

By automating tedious tasks, these machines significantly boost production efficiency. The lock screw machine quickly and accurately locks screws, the wire soldering machine seamlessly joins wires, and the glue dispensers speed up adhesive application.

Automation reduces labor costs and material waste, leading to substantial cost savings. The hot melt glue machine, for instance, optimizes glue usage, while the other machines minimize errors and scrap rates.

These machines are designed for versatility, able to adapt to a wide range of applications and materials. The automatic glue dispensers can handle various adhesives, the lock screw machine can accommodate different screw sizes, and the soldering and hot melt glue machines are suitable for diverse substrates.

Discover what our satisfied customers have to say about Company's exceptional products and services. Hear how our tower internals, packing, tower trays, and energy-saving solutions have made a significant impact on their operations, enabling improved separation processes and achieving remarkable energy efficiency.

Cooperate with us

The automatic glue dispenser has revolutionized our production process. The precision and consistency of glue application have significantly improved our product quality. The machine's efficiency has also allowed us to increase production while maintaining the same number of employees. The cost savings and material waste reduction are also notable benefits.

Rebecca

The automatic lock screw machine has been a game-changer for our assembly line. The speed and accuracy of screw locking have allowed us to significantly reduce production time while maintaining a high level of quality. The machine's ability to handle different screw sizes has also given us great flexibility. We are very pleased with the investment and highly recommend it.

Eastyam

We comprehend customers' needs throughout R&D and design, guiding us to craft functionally advanced products tailored to their specific requirements. Our commitment to enhancing product quality ensures that each offering exemplifies our dedication to delivering excellence.

Recognizing that each customer has unique needs, we offer customized solutions tailored to their specific operations and challenges. Our team of experts works closely with clients to understand their unique requirements and provide solutions that perfectly fit their needs.

We prioritize delivering outstanding pre- and post-sales services. Pre-sale, we offer detailed consultations to clarify product features and business benefits. Post-sale, we provide comprehensive support, encompassing installation, training, and continual maintenance, aimed at delivering a seamless and gratifying customer journey.