In the medical device industry, where lives are at stake, quality assurance holds the utmost importance. A manufacturer of surgical instruments, aware of this critical need, faced significant challenges in ensuring the precision and reliability of i...

In the medical device industry, where lives are at stake, quality assurance holds the utmost importance. A manufacturer of surgical instruments, aware of this critical need, faced significant challenges in ensuring the precision and reliability of its products, particularly in the assembly of screws. The slightest deviation in screw tightness could compromise the stability and functionality of surgical instruments, posing a risk to patients.

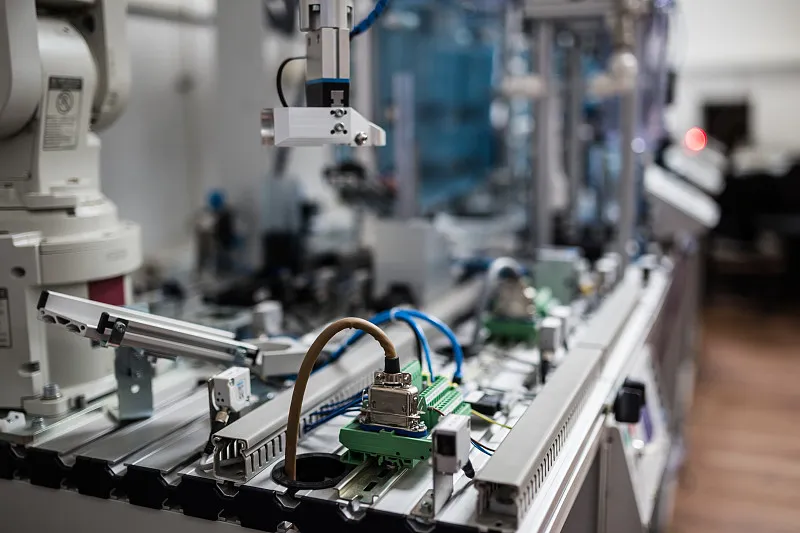

To overcome this challenge, the manufacturer decided to adopt an automatic lock screw machine. This advanced technology promised to address the issues of inconsistency and inaccuracy in manual screw tightening.

The introduction of the automatic lock screw machine transformed the assembly process. The machine's precision mechanics and sophisticated sensors ensured that screws were tightened to exact specifications, eliminating any room for error. This not only guaranteed a secure fit but also improved the overall durability and reliability of the surgical instruments.

The improvement in product quality was immediately apparent. With screws tightened to precise standards, the risk of failures and malfunctions during surgery was significantly reduced. This enhanced patient safety, which is paramount in the medical device industry.

Moreover, the improved quality of the surgical instruments strengthened the manufacturer's reputation. Customers, including hospitals and surgical teams, placed greater trust in the products, leading to increased market share and revenue.

The success of the automatic lock screw machine in medical device manufacturing underscores the importance of precision and reliability in this industry. By addressing the challenges of manual screw tightening, the machine has not only improved product quality but also enhanced patient safety and the manufacturer's reputation. This is a clear example of how advanced technology can transform traditional manufacturing processes, driving quality improvements and business growth.