Автоматските машини за прскање лепило значително ја подобруваат ефикасноста на производството. Компаниите кои ги користат овие напредни машини пријавија зголемување на брзината на производство до 30%. Автоматизирањето на процесот на наметнување на лепилото ги забрзува производствените циклуси и ја намалува зависноста од рачната работа. Оваа зголемена ефикасност им помага на бизнисите да ги намалат временските производи и ефикасно да се справуваат со сценарија со голема побарувачка.

Покрај тоа, овие машини обезбедуваат конзистентни и прецизни апликации на лепило, што го намалува отпадот и обезбедува еднакво прилепнување на сите производи. Истражувањата покажаа дека прецизноста што ја нудат овие машини може да ги намали трошоците за материјали за дури 25%. Со обезбедување на точна апликација на лепило, производителите можат да одржуваат висококвалитетни производи додека ги оптимизираат трошоците за материјали. Оваа двојна предност на зголемена брзина и намалена отпад го прави автоматските машини за прскање лепило вредно средство во модерните производствени средини.

Автоматските машини за прскање лепило се неопходни за подобрување на квалитетот и ефикасноста во повеќе индустрии. Во дрводелството и производството на мебел, овие машини се неопходни за создавање на силни зглобови и трајни завршни делови, значително зголемувајќи го естетскиот квалитет на крајниот производ. Истражувањата во индустријата покажуваат дека 70% од производителите на мебел сега се потпираат на автоматски апликации на лепило за да се обезбеди конзистентност и прецизност.

Во автомобилската индустрија, автоматските машини за прскање лепило се од клучно значење за лепило за поврзување на внатрешните компоненти. Тие обезбедуваат дека зглобовите се и силни и естетски пријатни, придржувајќи се до високи стандарди за изглед и безбедност. Неодамнешните извештаи укажуваат на растечка тенденција меѓу производителите на автомобили да ги прифатат овие автоматизирани решенија, признавајќи ја нивната улога во подобрување на квалитетот и ефикасноста на производството.

Покрај тоа, овие машини драматично ги рационализираат процесите на пакување и етикетирање, што ги прави витални во услови на производство со голем обем. Автоматизацијата ги намалува потребите за рачен труд и ја зголемува брзината на обработка. Истражувањата покажуваат дека користењето на автоматски системи може да доведе до намалување на трошоците за труд за 40%, што ги нагласува нивните финансиски придобивки. Овие различни апликации покажуваат како автоматските машини за прскање лепило нудат непроценлива поддршка на различни индустриски сектори.

Автоматизацијата ги трансформира производствените циклуси со тоа што овозможува континуирана работа без паузите потребни за рачен труд. Автоматските машини за прскање лепило се главен пример; тие можат да работат 24 часа во неделата, 7 дена во неделата, значително зголемувајќи ја продукцијата. Многу објекти известуваат дека автоматизацијата ги удвоила нивните производствени капацитети. Според експертните мислења, способноста за континуирано работење на овие системи без паундајм е клучен фактор во ефикасноста на производството.

Покрај тоа, влијанието врз времето за ставање на пазарот на производите е значително. Автоматизираните услуги за лепило ги забрзуваат процесите на наметнување и заздравување на лепилото, овозможувајќи им на производителите да ги скратат временските редове на производство и да го забрзат лансирањето на производите. Ограничените студии на случаи откриваат намалување на времето за изведување за до 50% кога се користат автоматски системи. Овој брз темпо не само што ја подобрува конкурентноста, туку и овозможува побрз одговор на барањата на пазарот, промовирајќи иновации и задоволство на клиентите во процесот.

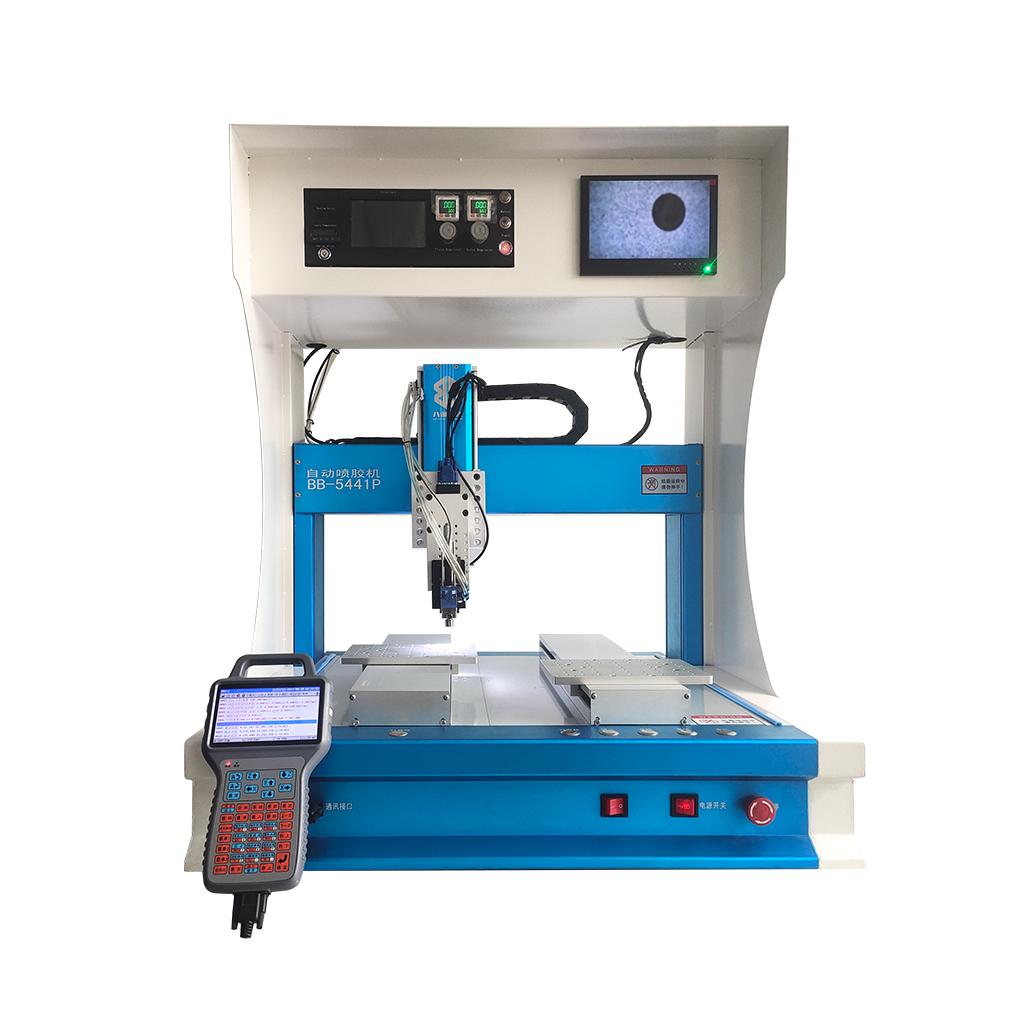

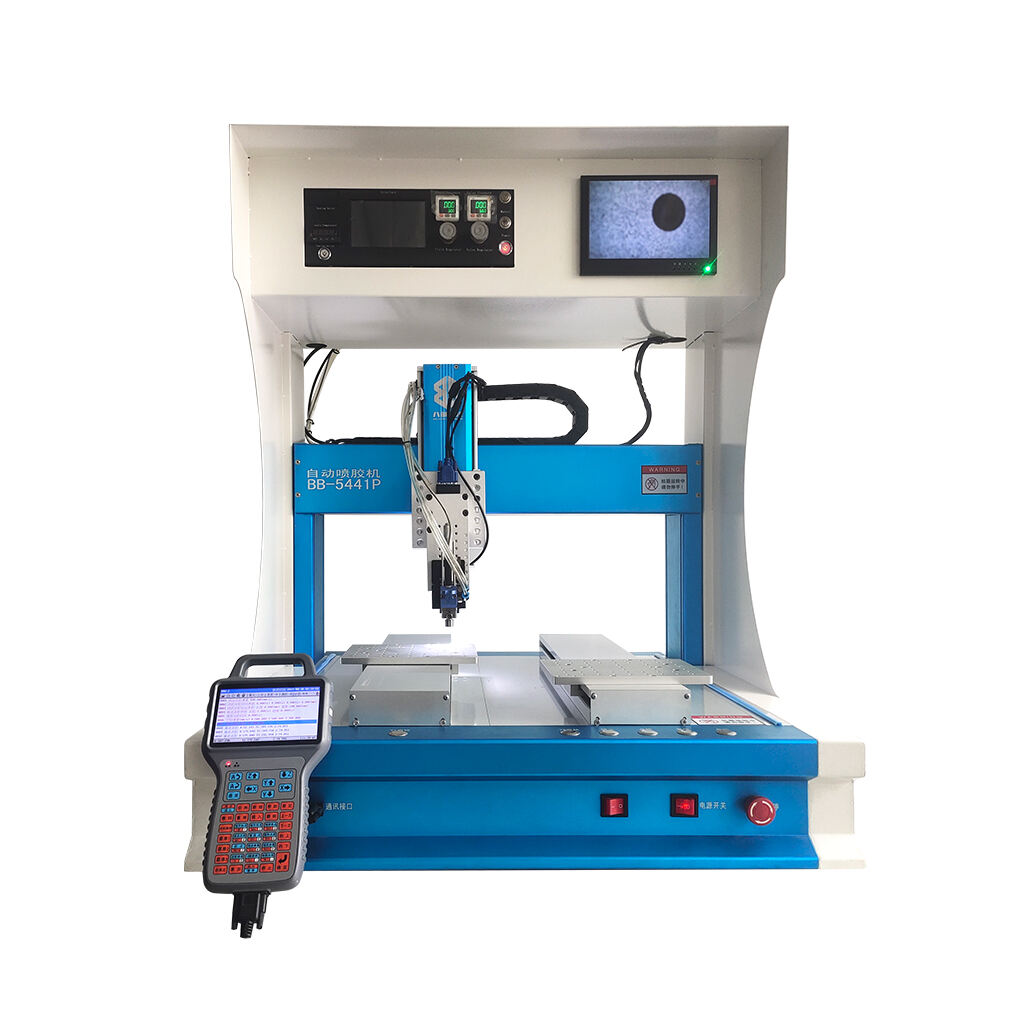

Автоматската машина за прскање лепило BB-5441P вклучува најсовремена технологија за подобрување на индустриските апликации за лепило. Тој има прилагодливи шеми на прскање и поставки на запремина, овозможувајќи прилагодување за различни задачи. Со максимална ширина на прскање од 1 метар и способност за загревање на топло растоплени лепила, таа е погодна за широк спектар на индустрии. Предностите вклучуваат намалено отпад на лепило, безпроблемна интеграција со постоечките производствени линии и постојана квалитет на производот. Извештаите на корисниците укажуваат на намалување на отпадот од материјали за 20%, што ја покажува ефикасноста и економичноста на BB-5441P.

Минимизирањето на прекумерното нанесување на лепило не само што зачувува ресурси, туку и значително го намалува влијанието на отпадни лепила врз животната средина. Автоматизирани системи како автоматски машини за прскање лепило можат да помогнат во намалување на употребата на лепило за до 30%, нудејќи по одржлив пристап кон производството. Ова намалување на употребата на лепила е од клучно значење за бизнисите кои сакаат да го минимизираат својот еколошки отпечаток, истовремено одржувајќи ефикасност и ефикасност во своите операции.

Одржливоста во производството станува сè повеќе фокусна точка за индустриите низ целиот свет. Автоматските машини за прскање лепило се усогласени со овој тренд со промовирање на еколошки практики кои го намалуваат јаглеродниот отпечаток на производствените процеси. Многу производители сега даваат приоритет на системи кои ги поддржуваат одржливите цели, осигурајќи дека не само што ги исполнуваат барањата на потрошувачите за зелени производи, туку и дека ги одржуваат високите стандарди за квалитет и интегритет на производите. Овој премин кон одговорност за животната средина се покажува како едновременно корисна и неопходна еволуција во модерната производство.

Интеграцијата со технологиите на Индустрија 4.0 ги подобрува можностите на автоматските машини за прскање лепак, нудејќи мониторинг и прилагодување во реално време. Со поврзување на овие машини со паметни технологии, како што е Интернетот на нештата (IoT), производителите можат ефикасно да ја следат употребата на лепилото и мерките за перформанси. Оваа поврзаност олеснува реактивна производствена средина каде што може брзо да се направат прилагодувања за да се одржи оптимална примена на лепилото, со што се подобрува оперативната ефикасност и квалитетот на производот.

Информациите базирани на податоци од овие интеграции на Индустрија 4.0 доведуваат до поинформирани процеси на донесување одлуки. Пристап до примерена анализа им овозможува на производителите да ги фино прилагодат своите стратегии за производство, оптимизирајќи ја за ефикасност на трошоците и квалитет на продукцијата. Истражувањата од индустријата покажуваат дека имплементацијата на овие технологии во процесите на примена на лепила значително ја зголемува оперативната ефикасност. Таквите подобрувања не само што ја рационализираат производството, туку и им овозможуваат на производителите да останат конкурентни преку искористување на најновите технолошки достигнувања.

Новите иновации во дизајнот на млазниците и прецизната контрола се клучни трендови во иднината на технологијата за автоматско прскање лепило. Овие достигнувања ветуваат уште пофина употреба на лепилото, оптимизирајќи ја употребата на материјалот и минимизирајќи го отпадот. Експертите од индустријата предвидуваат забележлив раст на технологиите за примена на прецизни лепила во наредните пет години, поттикнати од зголемената побарувачка за ефикасност и економичност во производството.

Вештачката интелигенција (ИИ) игра сè поголема улога во процесите на примена на лепило. Со автоматизирање на прилагодувања базирани на фактори на животната средина и спецификации на производите, вештачката интелигенција ја подобрува ефикасноста на операциите. Според експертите од индустријата, системите на вештачка интелигенција можат да учат од претходните апликации за да ја подобрат конзистентноста и да ги намалат грешките, потенцијално намалувајќи ги грешките во примена на лепило за околу 15%. Оваа еволуција не само што ја унапредува технологијата туку и придонесува за попаметни, адаптивни производствени процеси.