FPC automatic soldering machines for flexible circuit boards are increasingly used in high-end smart devices such as mobile phones, laptops, automotive parts and medical equipment, and often require precision welding processes to ensure their functio...

FPC automatic soldering machines for flexible circuit boards are increasingly used in high-end smart devices such as mobile phones, laptops, automotive parts and medical equipment, and often require precision welding processes to ensure their functionality and reliability.

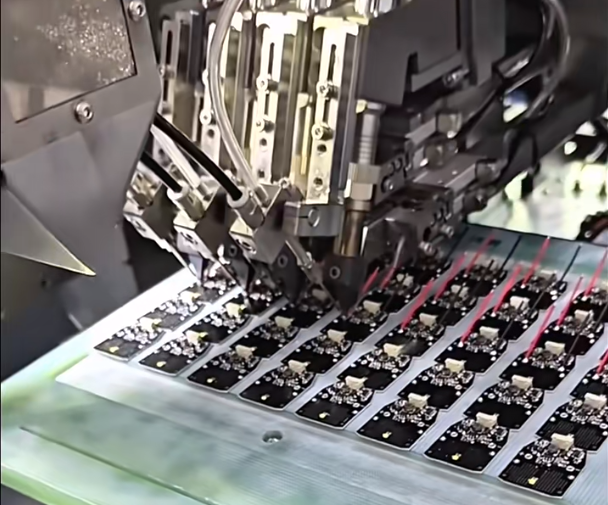

The technical parameters and functional characteristics of automatic soldering machine are very important for improving welding quality. For example, current Settings can be adjusted according to welding material and thickness to ensure welding quality. The use of multi-axis linkage manipulator and precision stepping motor drive can effectively improve the motion positioning accuracy and repeatability accuracy.

operating steps:

1. Before welding, apply flux on the pad and treat it with a soldering iron to avoid poor tinning or oxidation of the pad, resulting in poor welding.

2. Carefully place the PQFP chip on the PCB board with tweezers, taking care not to damage the pin, so that it is aligned with the pad, and ensure that the chip is placed in the correct direction.