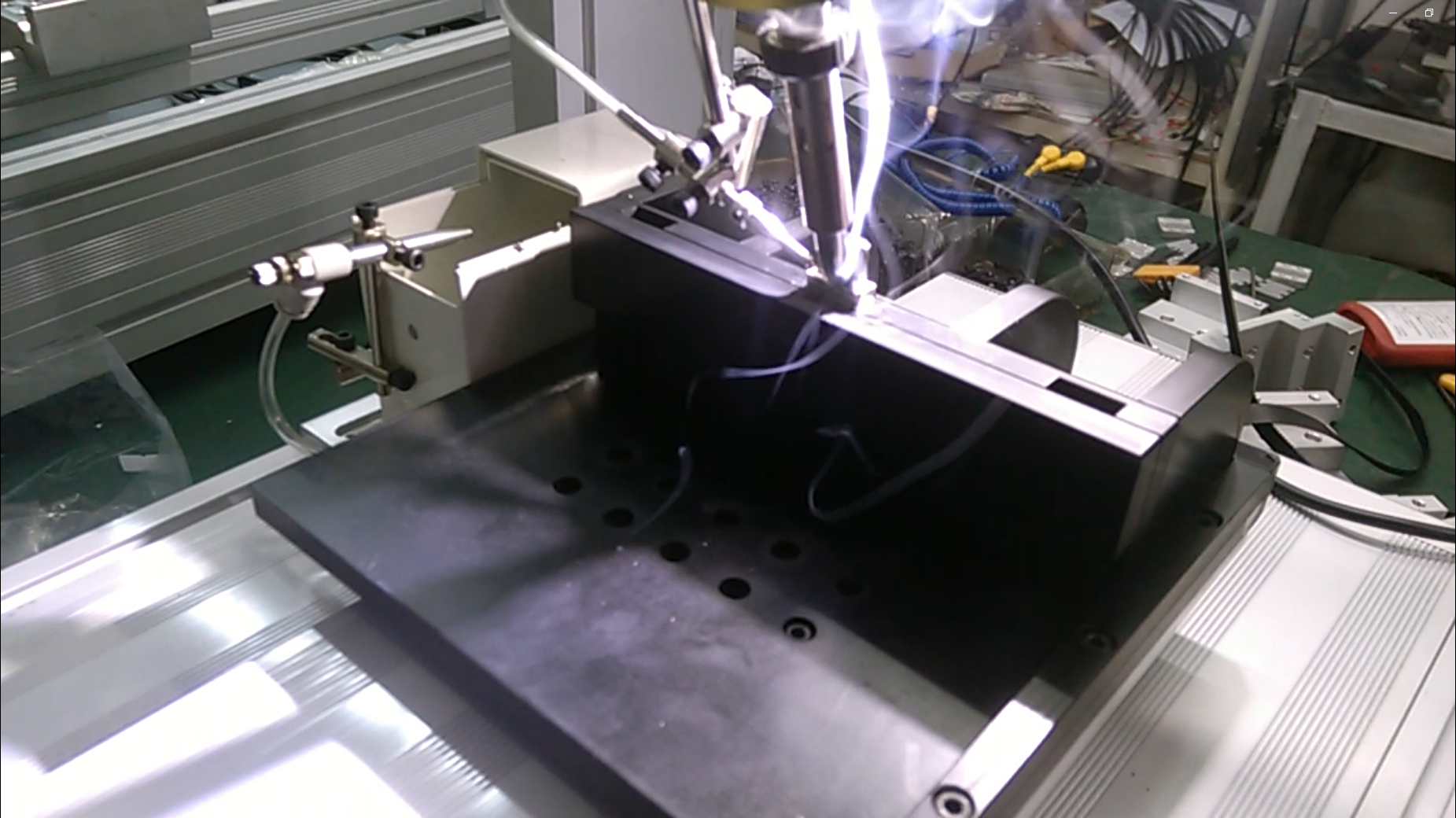

Camera wire automatic soldering machine has an important application in the production of mobile phone camera. Solutions can be considered in a number of ways:Welding technology selection:Laser welding technology: The application of laser welding tec...

Share

Camera wire automatic soldering machine has an important application in the production of mobile phone camera. Solutions can be considered in a number of ways:

Welding technology selection:

Laser welding technology: The application of laser welding technology in camera modules can provide reliable welding solutions in precision component welding and FPC (flexible printed circuit board) connection, and can also be used for automatic welding of vehicle cameras to improve processing efficiency.

Traditional welding technology: Traditional automatic soldering machine can also be used for camera wire welding. For example, eight on-line soldering machines, with CCD positioning, preheating, nitrogen and other functions, can meet the needs of multi-purpose automatic soldering.

Equipment selection:

High-precision automatic soldering robot: Select high-precision automatic soldering robot, you can set the process parameters by the customer to adapt to a variety of difficult soldering operations and micro-welding process.

Intelligent control system: The use of intelligent industrial control software, so that the human-computer interaction ability of the equipment far exceeds other peers. Solder joint trajectory program is compiled automatically, which can accurately control the temperature, Angle and tin amount of each solder joint.

Process parameter setting:

Temperature control: constant temperature welding method can avoid the phenomenon of tin explosion in the welding process. The unique temperature judgment analysis system can intelligently determine whether the welded body is solder paste or pad, so as to automatically adjust the temperature.

Parameter adjustment: The core part of the automatic soldering machine is the soldering system, which is mainly composed of the automatic tin feeding mechanism and temperature control, heating body and soldering iron head. These parameters can be adjusted according to the specific production needs to adapt to different welding processes.

Intelligent control:

Automated test equipment: Combined with the concept of modular design, automated line optical test equipment can meet the production test process of camera modules, suitable for camera modules or small optical components.

Machine vision system: The use of machine vision system for positioning and detection can further improve welding quality and efficiency.