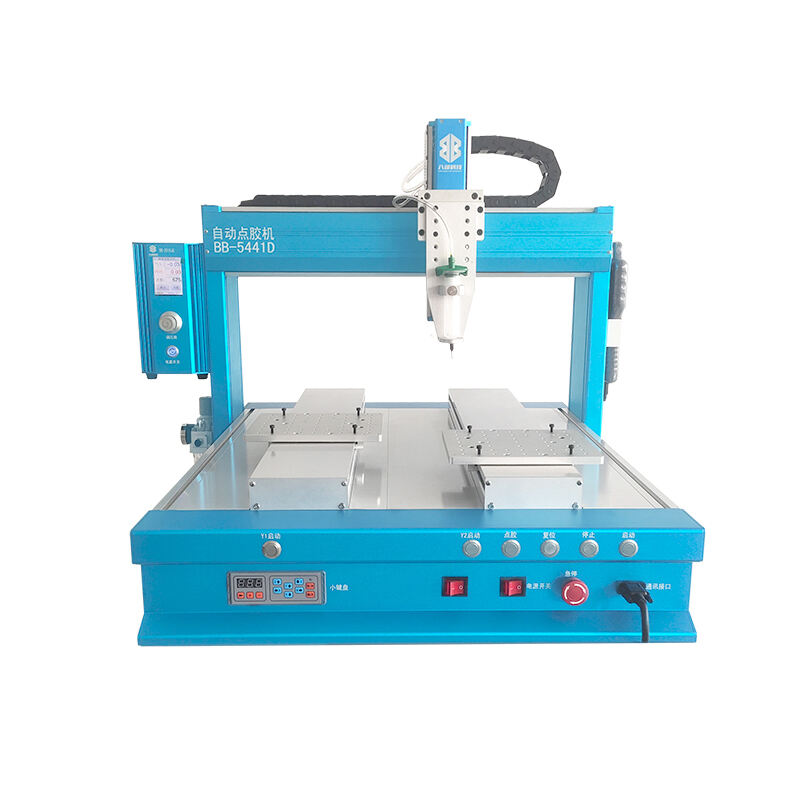

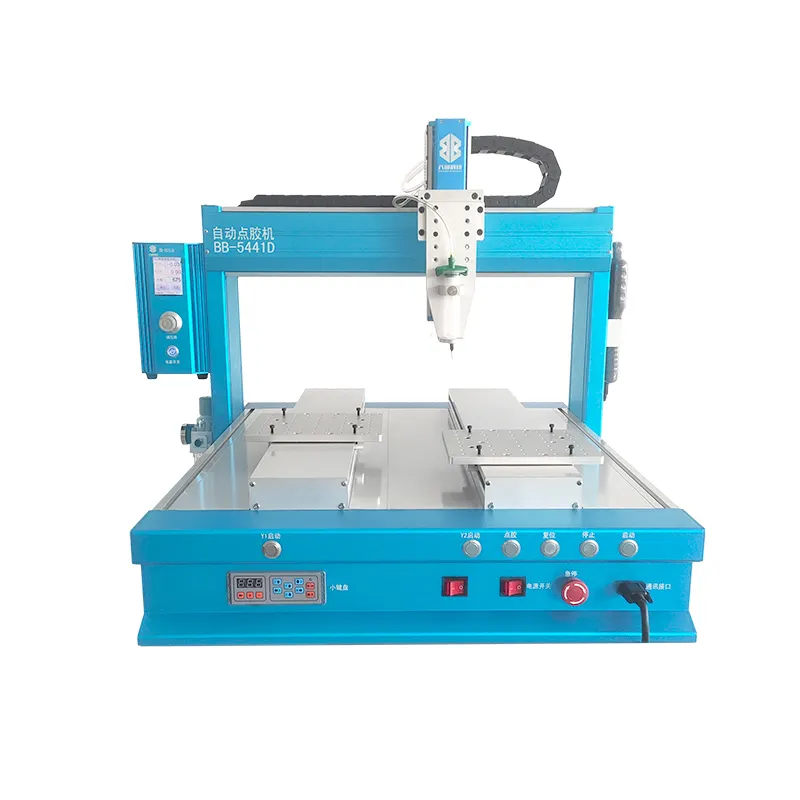

Automation is always welcome to the manufacturers. In this case, we will be using a high precision dispensing machine called BB-5441D Automatic Dispensing Machine. This machine targets accurate applications that require the drawing of circles and lines in a controlled environment in varying industries ranging from electronics and automotive companies

Why do circles require Control Machine

The BB-5441D has one feature that allows the machine to draw most shapes including circles, ellipses or sockets and even more. The operating system of the machine is controlled by very high precision allowing the operator to specify for example the diameter, radius, and the position of the circle so that it is drawn and is the same every time.

For example, in creating a standard circle more instructions can be programmed into the machine which will give it defined center point and radius, thus providing systematic geometry to the circle and maintaining integrity of the dispensing process.

Additionally, drawing elliptical figures or complex arcs using the BB-5441D is also possible. When three predetermined locations on the segment arc are chosen, the machine is capable of linking those three places to make an arc. This is an important function which is suitable for some production scenarios where a more specific and complex circle is required and such industry applications include electronics, where specifics are paramount.

This machine has drawing features, for example, straight lines that have a certain degree of precision. The straight line dispensing module within this machine however, is a device that isof importance for facilitating in line movement with minimal variations. This is achieved via rotation of the machine’s motor which assists in moving the workpiece along a straight line.

The straight line module is composed of high precision, high strength aluminum profiles and specially made sliders. Such solid construction serves to ensure that the machine remains parallel for a long though it may be used. Use of these heavy duty materials are important in ensuring the machine's accuracy is achieved even in high volume and lengthy production applications.

Manufacturing: Flexibility and Versatility

The features that stand out the most in the BB-5441D are its combination of circle and straight-line dispensing in a single process. This versatility makes it possible for the manufacturers to develop intricate and pattern designs which are composed of both shapes. When dispensing adhesive, silicone or any UV curing gels, BB-5441D’s 3D dispensing systems can be able to meet a range of production requirements.

For example, the machine's robotic arm has the free range of movement to both linear and circular arcs, and this allows it to perform very well in 3D dispensing applications. This also ensures that bonding, sealing and coating processes in industries in different applications can be highly integrated because correct amounts of the materials are dispensed along these paths.

Precision Control and High-Qualitative Work

The factors which determine the BB-5441D’s performance are the powerful engine and the precise control system. With an onboard controller and an advanced and very moderate dispensing system, the BB-5441D is able to make sure that every point of application is not only accurate but also reproducible. This helps achieve a high efficiency in the quality of the products while reducing the time spent in the production cycle.

The BB-5441D is well-suited for highly automated industries where a growing need for precision with complex structures or variable dispensing patterns is observed. Whether the task involves drawing a circle, a line or some complex shape, the machine manages to provide the degree of performance required in these bullish times.