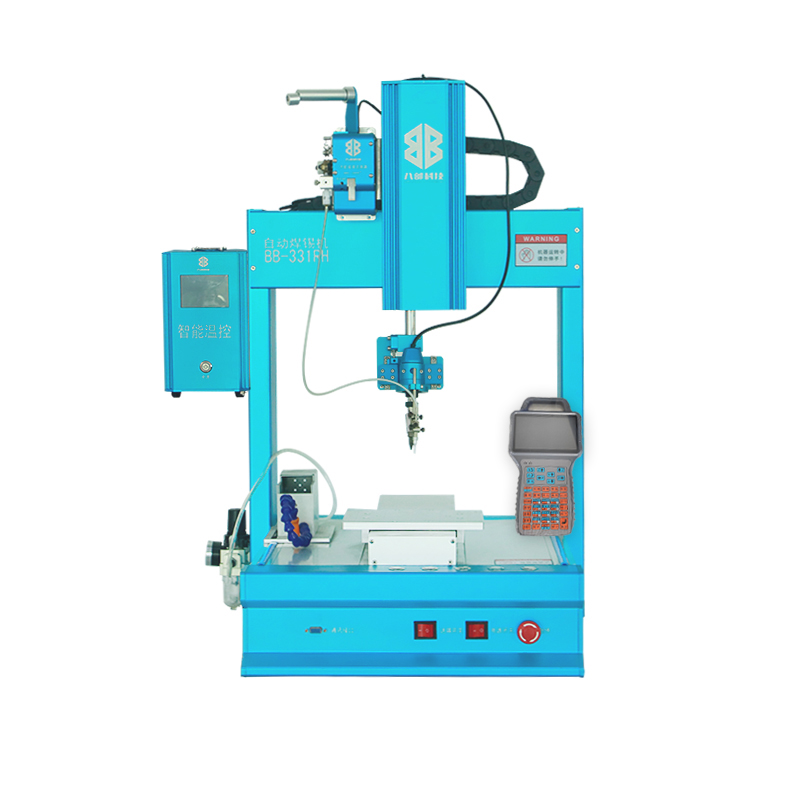

في مجال التطور السريع في تصنيع الإلكترونيات آلات لحام الأسلاك الآلية ظهرت كأدوات أساسية لتبسيط عملية اللحام مع تعزيز جودة وسرعة الإنتاج. فهم هذه الآلات وميزاتها يمكن أن يساعد المصنعين على تحسين عملياتهم وضمان إنتاج عالي الجودة. في هذه المقالة، سنقوم بالبحث في الجوانب الأساسية لآلات لحام الأسلاك التلقائية، بما في ذلك خصائصها وأنواعها وتطبيقاتها والابتكارات المستقبلية.

الآلات الحامية الآلية للأسلاك مصممة لتحديد عملية لحام الأسلاك والمكونات الإلكترونية. يلعبون دوراً حاسماً في ضمان أن يتم تصنيع مفاصل اللحام بدقة وموثوقية، مما يؤدي إلى نقص أقل ومستوى أعلى من جودة التصنيع. أوتوماتيكية لحام الأسلاك مهمة بشكل خاص في الإنتاج الحديث، حيث السرعة والدقة هي أمر أساسي.

الآلية في الحرار تجلب العديد من المزايا، بما في ذلك:

عند النظر في نماذج مختلفة من آلات لحام الأسلاك الآلية، هناك بعض الميزات التي تعزز أدائها بشكل كبير:

واحدة من أهم الميزات هي تحكم دقيق في درجة الحرارة .. هذا يضمن أن عملية اللحام تحدث في درجة حرارة مثالية ، مما يمنع مشاكل مثل الإفراط في الحرارة أو عدم كفاية التسخين التي يمكن أن تؤدي إلى ضعف مفاصل اللحام. النماذج المتقدمة تستخدم تقنية التحكم في PID للحفاظ على استقرار درجة الحرارة طوال عملية اللحام.

آليات تغذية اللحام الفعالة ضرورية لمواكبة متطلبات الإنتاج. آلات مجهزة بـ أنظمة تغذية لحام آلية يمكن أن يُوزع الكمية المناسبة من سلك اللحام بشكل ثابت، مما يعزز جودة المفاصل اللحام وتقليل النفايات. هذه الأنظمة غالبا ما تأتي مع أجهزة استشعار تراقب مستويات اللحام، مما يسمح للعمل دون انقطاع.

مُعدات اللحام الحديثة واجهات سهلة الاستخدام تسمح للمشغلين بسهولة برمجة ومراقبة الآلة. توفر بعض الطرازات أجهزة تحكم بشاشة اللمس تبسيط إعدادات سرعة اللحام ودرجة الحرارة وبارامترات أخرى، مما يسهل على المشغلين تحقيق نتائج اللحام المرجوة دون تدريب مكثف.

يمكن تصنيف المشهد المتنوع لآلات لحام الأسلاك الآلية إلى ثلاثة أنواع رئيسية:

هذه الآلات صغيرة الكمية و مثالية لإنتاج الحجم الصغير تصميمها يحتوي على ميزات سهلة الاستخدام تجعلها مناسبة لتطبيقات لحام مختلفة ، من النماذج الأولية إلى مهام الإنتاج البسيطة.

أنظمة اللحام الروبوتية مصممة لإنتاج حجم كبير. يستخدمون الذراعين الروبوتية لأداء مهام اللحام المعقدة، وغالباً ما يتم دمجها مع العمليات الآلية الأخرى مثل خطوط التجميع، مما يزيد من كفاءة الإنتاج.

مثالية للشركات ذات الطلبات الإنتاجية الكبيرة، يمكن أن تتعامل آلات اللحام عالية السرعة مع مئات مفاصل اللحام في الساعة. هذا النوع غالبا ما يجمع بين آليات لحام متعددة وبرمجيات متقدمة للبرمجة.

يتم استخدام آلات لحام الأسلاك التلقائية على نطاق واسع في إنتاج لوحات الدوائر المطبوعة (PCB) حيث يضمنون أن جميع المكونات متصلة بشكل آمن. لا يقتصر تطبيقها على الـ PCB فقط ، حيث أنها تستخدم أيضًا في أجهزة إلكترونية مختلفة مثل أجهزة الكمبيوتر والهواتف الذكية وأجهزة الكهرباء للسيارات .

في قطاع السيارات، هذه الآلات تلعب دورا حيويا في لحام المكونات التي تتطلب معايير عالية من الموثوقية والسلامة. مع زيادة تعقيد المركبات الحديثة، ازداد الطلب على حلول اللحام الآلي بشكل كبير.

صناعة الحرار تشهد تدفق التكنولوجيات الناشئة. وهذا يشمل دمج أنظمة رؤية الآلة التي تعزز دقة عمليات اللحام من خلال مراقبة وتعديل معايير اللحام في الوقت الحقيقي.

مع تحول الاستدامة إلى أولوية عالمية، يبحث المصنعون عن حلول لحام صديقة للبيئة. وهذا يشمل الآلات التي تستخدم لحام خال من الرصاص وتقلل من النفايات من خلال آليات تغذية الحام متطورة.

يغير ظهور إنترنت الأشياء العمليات الصناعية، بما في ذلك اللحام. الآلات الذكية قادرة الآن على إرسال البيانات إلى الشركات المصنعة، مما يمكنهم من مراقبة العمليات ومقاييس الأداء عن بعد.

مع تطور تصنيع الإلكترونيات، يجب على آلات لحام الأسلاك التلقائية التكيف باستمرار لتلبية احتياجات التقنيات والعمليات التصنيعية الجديدة، مثل المركبات الكهربائية وتقنيات الطاقة المتجددة.

س1: كيف تحسن الأتمتة جودة اللحام؟

ج1: الأتمتة تقلل من الأخطاء البشرية من خلال ضمان تطبيق متسق لمعلمات اللحام، مما يؤدي إلى مزيد من جودة مفاصل اللحام.

س2: ما هي أنواع المواد التي يمكن أن تعمل مع آلات اللحام الآلية؟

ج2: يمكن أن تعمل آلات اللحام الآلية مع مواد مختلفة ، بما في ذلك اللحام الخالي من الرصاص والحاميل ، اعتمادًا على قدرات الآلة.

س3: هل من السهل تشغيل آلات اللحام الآلية؟

ج3: نعم، معظم الآلات الحديثة تأتي مع واجهات سهلة الاستخدام، مما يجعلها سهلة نسبياً للعمل حتى للمستخدمين الذين لديهم أدنى تدريب.

س4: كم مرة تحتاج هذه الآلات إلى صيانة؟

ج4: الصيانة المنتظمة ضرورية لضمان أداء مثالي. ويشمل ذلك عادة تنظيف نصائح اللحام، والتحقق من المعايرة، وتحديث البرمجيات.

س5: هل يمكن تخصيص آلات اللحام التلقائية لتطبيقات محددة؟

ج5: نعم، العديد من الشركات المصنعة تقدم ميزات قابلة للتخصيص التي تسمح بتخصيص الآلات لاحتياجات بيئات الإنتاج المحددة.

في الختام، آلة لحام الأسلاك الآلية هي محورية في تصنيع الإلكترونيات الحديثة، وتقدم الدقة والكفاءة والقدرة على التكيف. مع تقدم التكنولوجيا، فإن ميزات وقدرات هذه الآلات سوف تتطور بلا شك أكثر، وضمان معايير إنتاج عالية الجودة في مختلف الصناعات. يمكن أن يؤدي تبني هذه التطورات إلى مزايا تنافسية كبيرة في سوق سريعة التطور.